Scientific project coordination

Hosted by the Institute of Polymer Materials, our group is working in the interdisciplinary research topic of design and characterization of interfaces between polymer and other materials. In practice, there are no sharp interfaces but rather interphases that are usually a few nanometers thick and can decisively determine macroscopic material properties. In this area the ideas of physics and chemistry, materials science and process technology meet. The collaboration of chemists, engineers, physicists and biologists leads to different perspectives and implementation routes on scientific purposes. Thus we are able to gain deep insights into existing and novel material concepts.

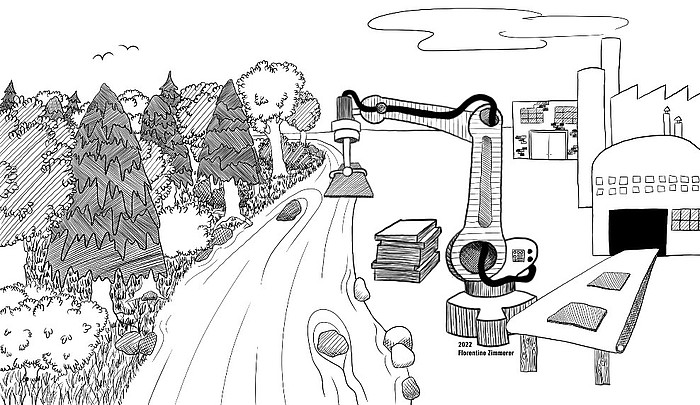

A smart, “green” combination of different materials, produced in eco-neutral or even eco-friendly industrial processes, is key to innovative, complex and application-oriented products.

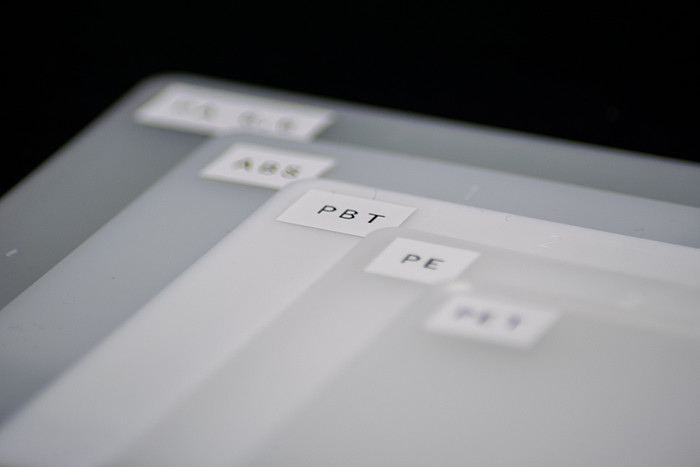

Our current work encompasses the generation of bio-inspired hybrid or composite polymer material concepts, esp. the chromium-free metallization of a variety of plastic types. Basing on biomolecules inspired by mussel adhesives, it allows us to identify environmental-friendly metallization technologies for established industrial product chains, and to open pathways for the recyclability of metallized products.

In the project InsBIOration we use natural polyphenolic materials as dopamine, tannic acid and their derivatives to promote adhesion between polymers and metals. They form a highly adhesive interphase between these basically incompatible materials. In composite and hybrid materials the quality of the interphases often determines the quality of the whole material. Hence, the work of chemists and materials scientists focusses on interphase design. In our project, we first deal with the fundamental understanding of the adhesion mechanisms. We explore ways to control adhesion and aim to develop techniques to create tailored adhesive interfaces that can be upscaled and are suitable for industrial production.

The bio-based adhesion promoters offer the possibility to chemically reverse the adhesion. This allows for re-use of reject parts and recycling of hybrid materials. In the project InsBIOration we explore the effect of enzymes, such as laccases and horseradish peroxidase, for the oxidative decomposition of the adhesive interphase [1]. The individual components of the composites are not affected by the enzyme treatment and can be retrieved as material mixtures. They can be separated e.g. in an electrostatic separator. For this purpose, we cooperate with the Hamos LLC company. As an example, for a complete recycling process, polymer substrates separated from plastic/metal composites were reused by the Kunststofftechnik Bernt LLC, while the coating metals can be recycled in a metal smelter.

[1] Zimmerer, C.; Kaiser, S.; Putzke, S.; Simon, F.: Process for recycling composite materials. Patent DE 10 2021 129 921 [Nov. 24th, 2021].

Scientific project coordination